Page 7 - Spec Tech Vol 1 Issue 04

P. 7

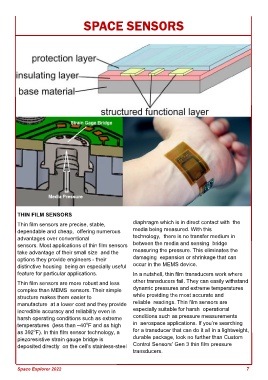

SPACE SENSORS

THIN FILM SENSORS

Thin film sensors are precise, stable, diaphragm which is in direct contact with the

dependable and cheap, offering numerous media being measured. With this

advantages over conventional technology, there is no transfer medium in

sensors. Most applications of thin film sensors between the media and sensing bridge

take advantage of their small size and the measuring the pressure. This eliminates the

options they provide engineers - their damaging expansion or shrinkage that can

distinctive housing being an especially useful occur in the MEMS device.

feature for particular applications. In a nutshell, thin film transducers work where

Thin film sensors are more robust and less other transducers fail. They can easily withstand

complex than MEMS sensors. Their simple dynamic pressures and extreme temperatures

structure makes them easier to while providing the most accurate and

manufacture at a lower cost and they provide reliable readings. Thin film sensors are

incredible accuracy and reliability even in especially suitable for harsh operational

harsh operating conditions such as extreme conditions such as pressure measurements

o

temperatures (less than –40 F and as high in aerospace applications. If you’re searching

o

as 392 F). In thin film sensor technology, a for a transducer that can do it all in a lightweight,

piezoresistive strain gauge bridge is durable package, look no further than Custom

deposited directly on the cell’s stainless-steel Control Sensors’ Gen 3 thin film pressure

transducers.

Space Explorer 2022 7